Test and Commissioning

We offer Testing and Commissioning solutions for all newly designed or commissioned Energy Facilities. Our testing and commissioning processes are carried out with our test devices that are periodically calibrated in accordance with the International Test Procedures prepared by our expert engineers. Following our Testing and Commissioning processes, the test results are evaluated and the necessary information about the safe energization and operating life of the equipment or equipment is presented with the test report.

ENERGY TRANSMISSION AND DISTRIBUTION CENTERS

- High voltage switchyard facilities testing commissioning services

- Air Insulated Switchgear (AIS) test commissioning services

- Gas insulated switchgear (GIS) test commissioning services

- Medium voltage switchyard facilities testing commissioning services

- Low voltage switchyard facilities testing commissioning services

- HV/MV/LV Cable Testing Services

- Grounding System testing Services

- Assembly/maintenance testing and commissioning services for Transmission and Distribution transformers

ENERGY TRANSMISSION AND DISTRIBUTION CENTERS

- Natural Gas Cycle Power Plants test commissioning services

- Hydroelectric Power Plants (HEPP) test commissioning services

- Solar Power Plants (SPP) test commissioning services

- Geothermal Power Plants (GPP) test commissioning services

- Thermal Power Plants test commissioning services

- Biomass & Biogas Power Plants test commissioning services

Expert staff

Unique Engineering

Technical support

Relay Test-Setting and Coordination Services

Protection relays used in high voltage systems are indispensable products for both human life and the healthy operation of the switchgear equipment to which they are connected. In order for a protection relay to perform its function correctly, when it is first installed in the field, it must be adjusted in accordance with the characteristics of the busbar to which it is connected and tested with a relay tester to ensure that the relay is working properly and that there is no error in the control circuit of the relay in the panel. Otherwise short circuit etc. in case of a malfunction; The switchgear facility to which it is connected, the transformer, engine etc. equipment to which it is connected, as well as the life of the person or persons in the field at this time will be in danger. For all these reasons, it is very important to test whether the protection functions of the relays in the field are working correctly.

Another issue is that in enterprises such as OIZs, factories, etc., which have more than one consecutive switchgear facility (distribution center), in case of a malfunction, making and testing relay coordination calculations and settings to cut off only the energy of the faulty point without cutting off the energy of the relevant facility is very important for the energy continuity of the business.

Our Relay Test Services for Protection and Control Systems

- Overcurrent / Ground Fault Relay

- Distance Protection Relay

- Protection Relays for warning systems

- Transformer Protection Relay

- Generator Protection Relays

- Feeder Control Relay

- Cable differential Relay

- Busbar Protection Relay

- Under/Over Voltage Relay

Transformer Testing Services

Considering that the operating life of transformers, which are widely used in all kinds of industrial or distribution facilities today, is approximately 20-30 years, periodic maintenance is of great importance for the continuity of the facilities. In this context, the services we provide as Enerzone Energy;

- Turning Ratio Test

- DC Insulation Test

- Transformer Oil Purification

- Loss Angle Power Factor Measurement

- Loss Angle Power Factor Measurement

- SFRA (Sweep Frequency Response Analysis) Test

- Excitation Current Measurement

- Transformer Step Test

- DC Resistance Measurement

- Chemical Oil Analysis Measurements

Our HV/MV/LV Cable Testing Services

As Enerzone Energy, we provide all kinds of testing services at the installation, acceptance and maintenance stages of energy cables, one of the most important equipment of electricity transmission. Our services regarding cable tests;

HIGH VOLTAGE CABLE TESTS

Enerzone Energy, with its expert staff, carries out tests and reports on all cable types up to 420 kV voltage level in high voltage cables.

- On-site commissioning, diagnostics and maintenance

- AC resonance testing system testing of extruded HV cables

- Tests in accordance with IEC 60840 and 62067 Standards

- High voltage tests

- DC resistance tests

- Capacity measurement tests

- DC insulation tests

- Zero sequence tests

MEDIUM AND LOW VOLTAGE CABLE TESTS

- MV and LV Power Cable VLF (very low frequency) Puncture test

- Pinpoint Detection of MV and LV Power Cable Fault Location

- MV Cable Tangent Delta tests

- MV Cable Partial Discharge tests

- DC Insulation tests

- MV cable Shield tests

Primary Equipment Testing and Commissioning Service

- Surge Arrester Tests

- Neutral Resistance Tests

- Voltage Transformer Turning Ratio Test

- Voltage Transformer DC Resistance Measurement

- Voltage Transformer DC Insulation Test

- Voltage Transformer Loss Angle Power Factor Measurement

- Voltage Transformer Excitation Current Measurement

- Voltage Transformer SFRA (Sweep Frequency Response Analysis) Test

- Current Transformer Turning Ratio Test

- Current Transformer DC Resistance Measurement

- Current Transformer DC Insulation Test

- Current Transformer Loss Angle Power Factor Measurement

- Current Transformer Excitation Current Measurement

- Current Transformer SFRA (Sweep Frequency Response Analysis) Test

- Breaker On-Off Time measurements

- Breaker – Disconnector Contact Transition Resistance Measurement

- DC Voltage Control

Generator Warning & Synchronous Systems Project Planning

Businesses need trained manpower, large investment costs and technology to meet increasing energy demands. At this point, automation and smart electrical infrastructure are now indispensable. Enerzone establishes turnkey systems on issues such as warning and excitation systems, generator protection, synchronization systems, energy billing and automatic meter reading. We also offer services such as primary and secondary frequency control and reactive power control as our ancillary services. If we list our power plants services;

- Warning and Excitation Systems

- Synchronization Systems

- Protection Systems

Warning and excitation systems have a great impact on the dynamic performance of the generator. Warning and excitation systems determine the quality of generator voltage and reactive power, in short, the quality of energy distributed to all electricity users. The main function of warning and excitation systems is to provide variable DC current with short-term overload capacity, control the output voltage with appropriate accuracy, ensure stable operation, communicate with the power plant control system and ensure that the generator operates within operating limits.

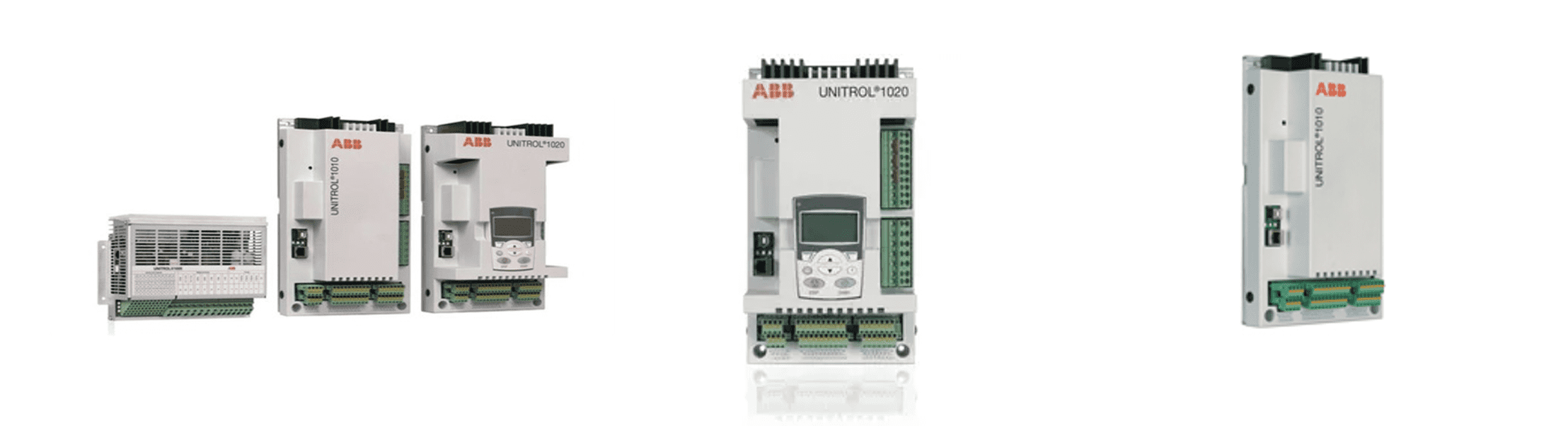

In the systems we install, we use ABB’s UNITROL series microprocessor-based voltage regulators with rotary excitation and static excitation systems for all kinds of synchronous machine (motor and generator) control.

There are different stimulation systems;

- Brushless excitation systems

- Rotary excitation machine and automatic voltage regulator (AVR)

- Static excitation systems (SES) that feed the rotor directly via a thyristor bridge over brushes

The advantages it provides;

- Customer-oriented standardization

- Customer-specific system solutions

- Compliant with ISO 9001/ISO 14001 quality management systems

- Worldwide commissioning and maintenance services

- Fast commissioning and maintenance time thanks to easy-to-use software tool